Aluminum Prop System | I-PROP

I-Prop, the aluminum support prop according to standard EN 16031 for high load capacity. This system is suitable for all types of ceiling.

This prop allows you to reach greater heights with higher capacities than steel props. Made entirely of aluminum, it combines these great performances with the possibility of manual handling. It makes work procedures faster and safer, guarantee time and cost savings.

Compared with tubular steel slab props this aluminium prop carries significantly higher loads whilst, at the same time, has a very low dead weight.

The prop is available in two variants:

- natural aluminum

- powder coated

This prop system can be used as individual props and, in combination with frames, as shoring towers or load towers under tables.

The prop can be used indifferently with the inner tube downwards or upwards, while the base plates are suitable for receiving the connections of accessories or the overlapping of the prop itself.

A load of the support I-PROP is up to 100 kN possible, in connection with connector frames can support the tower up to 12 meters height.

Light-weighted

High load-bearing capacity

Economically

Efficient

Can be built up

Projects & References

Reconstruction of the Himera Viaduct – A19 Palermo-Catania

For the reconstruction of the Himera I viaduct, which was demolished after the landslide damage on April 10, 2015, Interfama supplied the following formwork systems: MAXIM wall formwork and the ALUSTERN and I-Prop support systems for support.

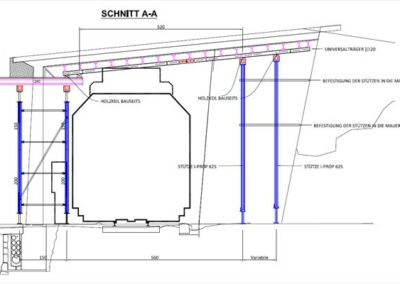

Renewal of the Galerie Grüm railway line St. Moritz – Tirano

For the renovation of the Alp Grüm Galerie on the St. Moritz – Tirano railway line, INTERFAMA supplied the ALUSTERN support system, I-PROP625 aluminum supports and special steel girders for a portal span of 5.6 meters. The entire demolition and concreting work was carried out without interrupting the railway line.